06.06.2004

Virtual Reality Life in Action

Worldwide factory planning cooperation in international planning teams

Students at the Department of Production Management participated for the first time in the international business game "FIT2011" for virtual factory planning in international planning teams. The business game is based on a scenario that Prof. Dr.-Ing. Harald Augustin, a former employee of the University of Kaiserslautern, developed: "Since the summer semester of 2003, we, as a faculty of the Reutlingen University of Applied Sciences, have been a member of the university network for virtual factory planning, to which the universities of Karlsruhe, Perdue (USA), Warsaw (Poland), Helsinki (Finland) and Metz (France) belong in addition to the leading university of Kaiserlautern.

The aim of the simulation is to confront the students with a planning situation for factory planning based on real data, in which they can apply the methods and procedures learned during their studies. In addition, the students also learn how to work in interdisciplinary and international, culturally mixed teams.

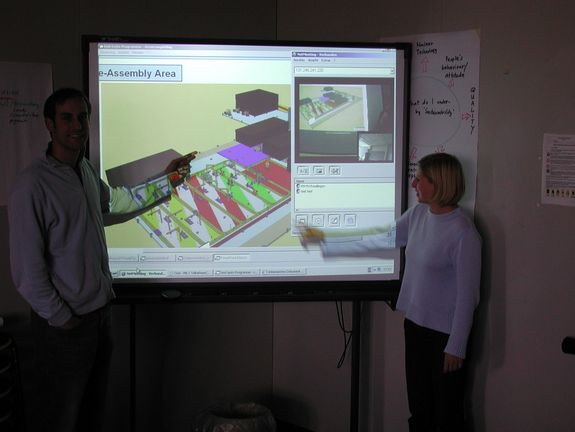

To make matters worse, the teams are made up of students from the participating universities, so that they are dependent on the application of modern information and communication technologies, e.g. document management systems, collaboration tools, video conferencing systems, etc. A new addition this year is a software from the field of Virtual Reality (VR) developed in Karlsruhe (see picture), which simulates a planning room in which the team members can meet virtually at the same time and can place their machines and equipment in the virtual factory hall and optimise the flow of materials. "The development of the software to be used is constantly being advanced in order to always simulate an innovative and practice-oriented working environment," says Prof. Dr. Augustin.

The work done by the students was fascinating, as the teams worked together until early in the morning due to the time differences. After four days of hard planning work, the results were presented and evaluated by the teams via video conferencing in a virtual management meeting. The students' conclusion was very positive and everyone agreed that this was one of the most outstanding events in the entire course of studies. From the point of view of the supervising professors, Prof. Dr. Augustin concluded that "this positive feedback is of course a further incentive for us to further develop the business game and to gain additional partners who are involved in the university network. At the Faculty of Production Management, students took part for the second time in the international planning game "FIT2011" for virtual factory planning in international planning teams. The planning game was developed by Prof. Dr.-Ing. Harald Augustin, head of the study program Master of Science in Logistics Management. Since his move to Reutlingen University, the Faculty of Production Management has been a member of the university network for virtual factory planning, which includes the coordinating University of Kaiserlautern as well as the universities of Karlsruhe, Perdue (USA), Warsaw (Poland), Helsinki (Finland), Athens (Greece) and Metz (France).

In this planning game, students learn how to apply the methods and procedures learned during their studies to a factory planning based on real data. Factory planning becomes virtual by the fact that the planning teams are made up of students from the participating universities, who thus have to work together in interdisciplinary and international, culturally mixed teams. For this kind of cooperation, for example, a 3D virtual reality tool for simultaneous factory layout planning in spatially distributed teams is used. The final presentation after four strenuous days, during which work was sometimes carried out into the night, impressively demonstrated the excellent planning results of the groups (see picture).

In the application of more advanced Digital Factory tools, the training of future industrial engineers "Made in Reutlingen" also opens up new perspectives. "Starting in the winter semester 2004/2005, we will offer a completely new type of role-focused, international business games that integrate industrially used software from product data management to professional meeting systems to VR planning tools with simulation options. First sponsors have already been found in the form of the companies Parametric Technology (PTC), Munich, and CoCreate, Sindelfingen, as well as a Fraunhofer Institute. Negotiations with further companies are ongoing. When we start the business games ViPPER (Virtual Product and Process Engineering) and ViSLER (Virtual Supply Chain and Logistics Engineering) in real operation in the winter semester, the training of industrial engineers will open up a new dimension that is unparalleled in Germany. The age of the digital factory will then be reality for us and offer development potential for the next 5 to 10 years. In this area, we will in particular develop new training methods for Virtual Collaborative Engineering (VCE) and make them accessible to industry," says Prof. Dr.-Ing. Harald Augustin.

![[Translate to English:] Vielfalt gestalten [Translate to English:] Vielfalt gestalten](/fileadmin/_processed_/1/b/csm_vielfalt-gestalten_ada6a17851.png)

![[Translate to English:] Prime [Translate to English:] Prime](/fileadmin/user_upload/prime-logo.png)

![[Translate to English:] Weltoffene Hochschule [Translate to English:] Weltoffene Hochschule](/fileadmin/_processed_/d/7/csm_logo-weltoffene-hochschule_6f9b27df1e.png)